Understand LED flexible line lights in one article

Time:2020-12-24

Views:52

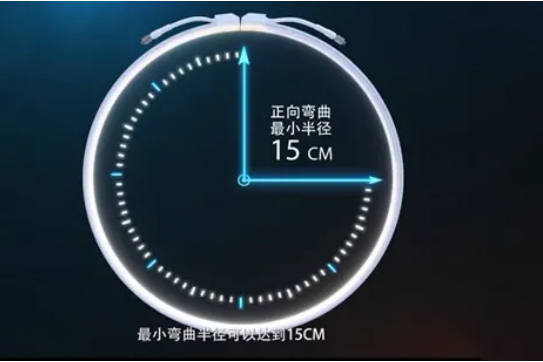

Literally understood, LED flexible line lights are an upgraded version of LED line lights. It not only has the basic functions of LED line lights, but also shows its "flexibility"-based differences on this basis. Because of its flexibility, LED flexible line lights can be installed on a curved surface, which has become the most intuitive innovation point different from traditional LED line lights. In modern architectural design, designers have already abandoned the past matchbox-style stacking, and then pursued novel creativity in art and culture, so as to make the appearance of the building more colorful. Judging from the characteristics of traditional LED linear lights, no matter in terms of fitting, interface, wiring installation, etc., it cannot meet the requirements of modern building applications, making the building facades. LED flexible linear lights can be bent around 15CM. The radius makes up for the shortcomings in this respect, allowing architects to have more room for imagination, and to create more visual special shapes for the appearance of the building.

Bending radius of LED flexible line

Convenient installation, full application advantages

In practical applications, the advantages of LED flexible line lights are embodied in their split installation design. The traditional LED linear lamp is like a chandelier integrating the light source, external structure and circuit. If the lamp is broken, the entire lamp body must be disassembled and replaced with a new chandelier.

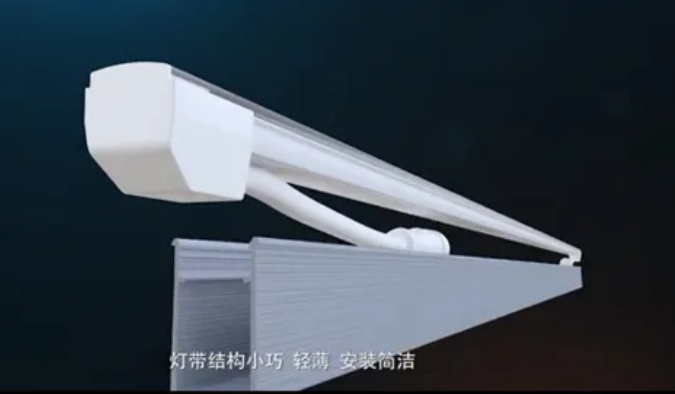

The mounting bracket of the LED flexible line lamp is separated from the main body, and the middle is installed in a physical buckle type. If the lamp is broken, the main part of the light source can be replaced like a light bulb, which is very convenient. The difference between the installation and replacement of the LED flexible line lamp and the traditional LED line lamp seems to be very small, but from the perspective of the later maintenance of the lamp and the operation of the maintenance personnel, the difference is very large.

Split snap-in installation

The biggest problem in landscape lighting projects, the maintenance and operation of lamps and lanterns is the key to the success of a project. As we all know, a skilled installation technician can install about 40-60 traditional LED linear lights a day, but if this type of product is replaced, the replacement rate may be less than 10 a day.

The reason is that the weight of traditional LED linear lights is generally 1-1.5 kg per meter, and the requirements for installation are relatively high. Some even screw the lighting installation screws to the main dragon linear lights on the building curtain wall for stability. ; On the other hand, the waterproof measures on the wall are relatively good at the first installation, but when the whole lamp is disassembled and replaced, it is difficult to restore the original waterproof level, which makes the original lighting maintenance and operation become a building Curtain wall maintenance and operation. For this reason, skilled workers often have to sacrifice the efficiency of replacement to avoid damage to the building structure and the waterproof structure of the lamp body caused by the secondary installation.

With the light weight of about 0.2-0.3 kg and the characteristics of being installed on a decorative cover that does not involve the waterproofing of the building curtain wall, the LED flexible line lamp has its advantages in the later maintenance and operation of the project. With its split design, you only need to pull out and replace the LED flexible line lamp when the lamp is reinstalled, eliminating the worries of waterproofing and curtain wall maintenance.

Application effect of LED flexible line lights in builders

To

From the perspective of maintenance costs, the service life of a luminaire is a problem that must be considered in the project. If the service life of a luminaire is 5 years, and the service life of a skyscraper is 100 years, then if you want to keep the lamps in use all the time , That would have to be replaced 20 times. Putting aside the problem of cost, the traditional LED linear lamp requires at least 4 screws per meter, and if it is replaced 20 times, there will be 80 screw holes per meter. For the curtain wall structure, the high repair cost caused by the damage caused by the screw hole can be imagined.

In terms of cost, in the cost distribution of a lighting project, lamps and lanterns account for about 25%, and cable and pipe, strong and weak current control and labor account for about 75%. Compared with lamps, cable conduits have a longer service life and can be replaced for decades. The strong and weak current control is usually installed indoors, and maintenance and replacement are more convenient. However, the lamp is a complex of electronics and structure, especially with control The service life of signal lamps is estimated to be only 5 years. What‘s more, like traditional LED linear lights, the cost of dismantling the lights in high-altitude operations is much higher than that of new installations.

To

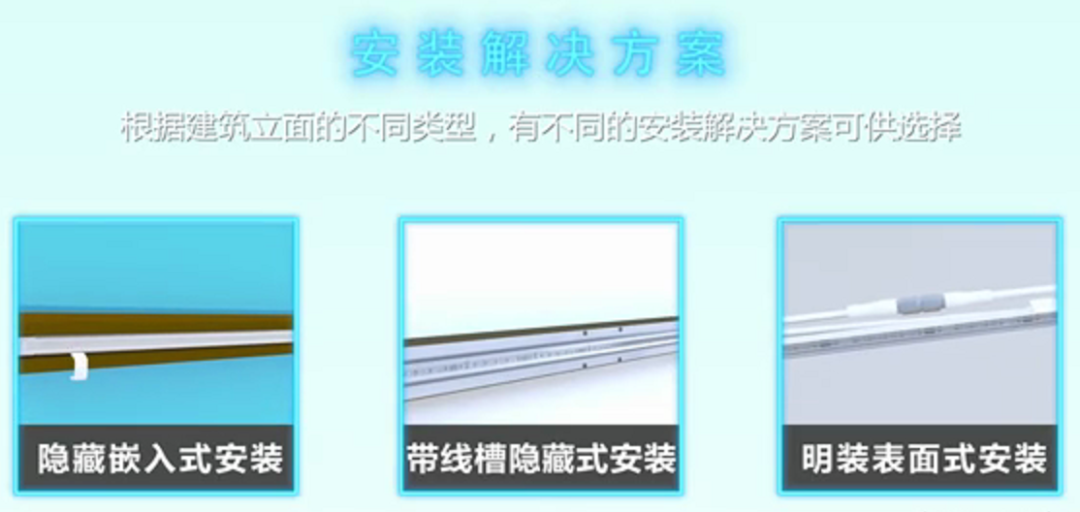

Different installation schemes of LED flexible line lights

For this reason, LED flexible line lights rely on the advantages of split design and physical snap-in installation, which can easily be replaced by hundreds of meters a day, just like changing a bulb. In addition, since the entire replacement process does not need to move the mounting bracket body, and does not affect the strong and weak current lines and other related equipment, the use of LED flexible line lights greatly reduces the cost of replacement.

In terms of cost arithmetic and logical reasoning, after using LED flexible linear lights, the maintenance cost of lighting projects is much lower than traditional LED linear lights. Of course, the most important thing is that as long as the brackets installed for the first time are stable enough, every replacement will not cause secondary damage to the building structure, greatly improving the life and sustainability of the entire project, including the lamps and lanterns. .

At least five aspects meet outdoor application requirements

Compared with traditional LED linear lights, LED flexible linear lights have many market competitive advantages. However, in the eyes of many designers, engineering companies and Party A, there is a lot of fear for the emerging flexible plastic products. Because many users have encountered a series of problems in the process of using this kind of products, such as falling off, yellowing, water ingress, and aging. These are common phenomena in the use of flexible plastic products, because most of the current flexible plastic products are made of high-voltage LED lights and LED strips.

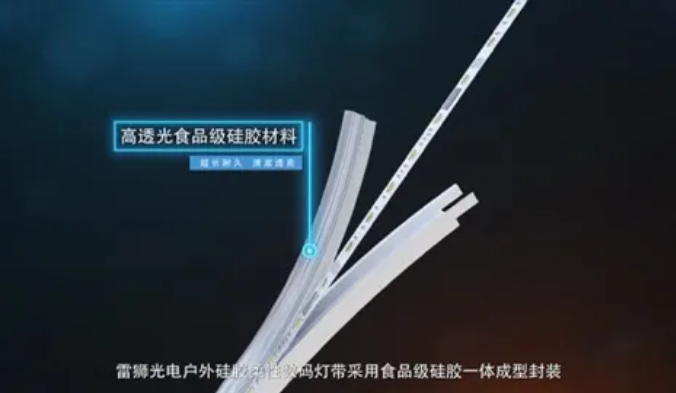

Silicone material for LED flexible line lights

High-voltage LED Meinair lamps are usually used for decoration. The principle is to connect multiple LEDs in series with wires, seal them with glue, and directly input high-voltage or make a simple RGB color-changing external control. The method is the same as the Christmas light string, except that the LED Meinian lamp integrates multiple LEDs into the outer envelope. Because it is made through simple synthesis, it cannot withstand long-term outdoor applications. It can only be used in the decorative field, such as the tree-winding lights for festivals and the contours of architectural decoration ditches. The application is two different concepts from LED linear lights. , The former is a decorative lamp, and the latter is an architectural functional lamp. In the past, many users believed that LED Meinian lamps had extraordinary connectivity, and used them as LED linear lamps, which caused a lot of abnormal quality.

On the other hand, LED light strips are the most impressive concept for users of flexible plastic products, including LED flexible line lights, which are also classified as LED light strips. Later, it was discovered that there was a big difference between the two in the promotion process. The difference. At present, there are generally two production processes for LED light strips on the market, casing and glue. In the past two years, the extrusion process has also appeared, and the materials used are mostly PVC, PU, ??silicone, plastic, etc.

The manufacturing principle of the extrusion process is to weld the LEDs in series and parallel using flexible circuit boards, and then encapsulate them twice. Compared with LED Meinair lamps, the products made by this process have high stability and diversified functions. Many LED strips with DMX signals also use this process. The extrusion process widens the application range of LED light strips, such as indoor dark groove light transmission, advertising light box backlight, weak outdoor applications and other applications. Even so, LED light strips still cannot be compared with LED linear lights on the application level. Without the reference of relevant national technical standards, in my opinion, a real LED flexible line lamp must meet the requirements of outdoor applications in at least five aspects, namely, yellowing, anti-off, waterproof, weather resistance and circuit reliability. These 5 aspects are not difficult to realize for traditional LED linear lights, but not easy for LED flexible linear lights. Below is a brief overview of my requirements for these five applications:

The real cause of yellowing is caused by ultraviolet rays irradiating the externally sealed colloid. Its source is the ultraviolet rays of the sun and the ultraviolet rays emitted by the LED itself. In comparison, the ultraviolet rays of the latter are more harmful than the former, especially white light. LED and blue LED. The standard is to maintain the colloidal light transmittance of more than 70% in the working state in the sun environment for 10 years.

The concept of anti-dropping is mainly considered from two aspects of thermal deformation and physical deformation. In terms of thermal deformation, we require 100% complete solid form at a temperature of 250° and no structural collapse in the 960° burn test. The minimum physical deformation requirement is IK06 or above. Impact resistance level.

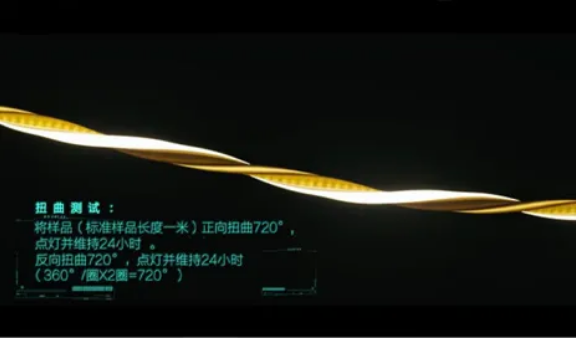

Twist test

The waterproof grade is IP67 as the standard grade, and the weak outdoor use should be at least IP65 or higher. It is strongly not recommended to use the IP68 grade outdoors.

water-proof test

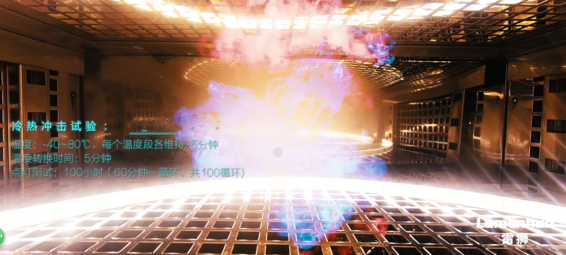

Weather resistance is a hard core condition to test whether it can be used outdoors, and it is more a product reliability process test, such as high and low temperature environment test, structural weather resistance, acid and alkali weather resistance. If the manufacturer does not have the ability to conduct self-testing experiments for this application, and the cost of entrusting third-party inspections is too high, most of these inspections are not carried out. If the product does not pass the testing required by the application, it will open up the quality gap of similar products, and bring great uncertainty to outdoor engineering use.

100 cycles of high and low temperature thermal shock

To

Circuit reliability is another important factor that determines product quality. Compared with the FR4 board of the LED linear lamp or the single-sided FPC board of the LED strip, the circuit reliability is not so important, because it is a mature process. The LED flexible line lamp has many functional requirements, and the multilayer FPC soft board is used, which has high requirements for circuit design and welding of electronic parts. How to do a good job in the design end, the welding inspection of multilayer FPC soft board materials and electronic parts, tests the enterprise‘s manufacturing skills and level in this type of product.

On the one hand, special attention should be paid to the stable quality of the multilayer FPC circuit in physical bending; on the other hand, the multilayer FPC also carries the thermal conductivity of electronic devices, and the design requirements of the FPC and the thermal conductivity of the secondary coating glue It also has very high requirements. After all, the LED flexible line lamp is a fully encapsulated one-piece product, and heat conduction and heat dissipation are also an important technical issue.

Brands:RayNeon® RAYTA®

Brands:RayNeon® RAYTA®

Wechat

Wechat